Product Description

After purchasing and receiving the goods, please pay attention to the following items:

NOTE: The power must be cut off before the Epson print head is installed, otherwise it will cause the print head’s circuit board to be burned out.

1.When the print head is shipped, it will be coated with a protective liquid. When using it for the first time, wipe the print head before installing it. The protective liquid drops on the chip and where the ink bleeds. And use tissue to gently wipe the protective liquid on the chip ( on the copper sheet). Don't use cleaning fluid or eraser.

2.During the regeneration process of the print head, the original ink will be cleaned and the protective liquid will be injected. If there is no protective liquid, printing will not be done when the pipeline is dry. If the print head can be detected, but color irregularity or blurry is observed, you can continue to add ink to print, print sheets to use up the protection liquid. And then the color can be used to print.

3. If the printing is not clear, press the cleaning button of the machine. And the print head can be cleaned when the ink cartridge is full of ink. If there is no ink to clean the print head, it is easy to be burn out. And you can print clearly after printing a few times.

4. Clean the print head directly on the machine instead using cleaning fluid. If you clean it with cleaning fluid and do not drop the protective fluid, the print head will be completely blocked and can not be used.

5. Don't use cleaning fluid or water to clean the print head, otherwise the print head will be completely blocked.

When replacing the print head, please pay attention to the following items:

1.After receiving the print head, do not use a needle tube to inject water to check if the print head is blocked. It is a useless and dangerous practice. First of all, once the print head gets water and is not dry, and power on the machine, the main board will be burned out , and even the print head will be burned out .

2.The head surface of the print head is very fragile. It must not be touched, and needs to be protected. Its surface is an aluminum sheet, and inside is coated with a crystal oscillator and a very small ink tube. It will be deformed or even broken when touched, and the print head will be scrapped.

3.Be careful when installing the print head, be sure to cut off the power first, and install it in place. After installation, please push gently with your hands. Do not power on after installation, because if the head is not in place, the head will easily break when the machine moves. But your hands can feel, and it is easy to control.

4.When connecting the plug cable, do not be with ink. And make sure to make good contact with the socket and not touch the feet. Otherwise, it will cause the print head to short-circuit and burn.

5.The steel shaft should also be clean and smooth. Use tissue to stick some lubricating oil to wipe it off. Do not directly add oil to the shaft because excess oil will flow to the print head and cause damage.

6.After confirming that the machinery and circuit are normal, it is necessary to check the water circuit. First, check whether the amount of water in the ink cartridge is sufficient or not; second, check whether the small cleaning blade and the ink pump are dirty or not.

7.There will be air in the newly installed print head, so it will not print normally immediately. Only after the air in the print head is completely exhausted can the lines be printed normally. First of all, you can use the machine's cleaning function to perform intermittent cleaning ( two cleanings each time,and then two more cleanings after a 30-minute pause). Excessive cleaning for many times will cause ink accumulation in the cleaning pump. It will not only cause color mixing and ink leakage, but also waste ink.

8.Secondly, you can print more pictures to let the print head exhaust air during work. Third, if the machine has already take brought out the waste ink tube, you can cut off the power first, and then use a rubber tube to draw out the waste ink until 3-5ML of ink is drawn out. Next, turn it on again, and normally clean it once with the machine. That is, the air in the print head is artificially pulled out, but the side effect is that it’s easy to cause ink accumulation in the cleaning pump.

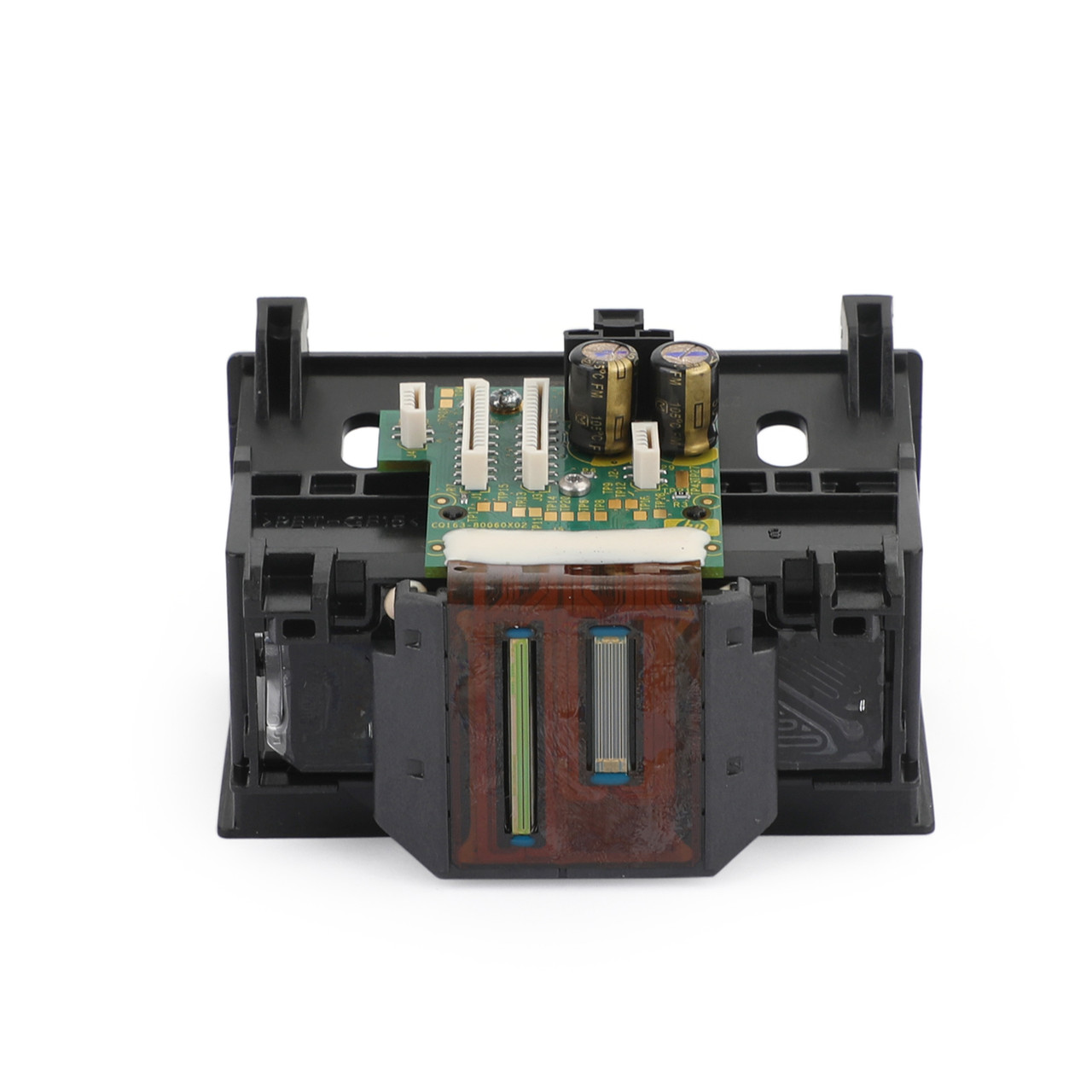

Feature:

Excellent performance and high quality.

Made of high-quality material, durable, firm and stable for us to use.

This is a cleaned, thoroughly tested and sealed Printhead.

Good stability, long lifespan.

Full color function.

This is Aftermarket Replacement Item But Not Genuine.

Size:90x45MM

OEM Part Number: CQ163-80060

Compatible Models:

Refurbished 934 935 Printhead

Fit For Hp Officejet Pro 6230

Fit For Hp Officejet Pro 6830

Fit For Hp Officejet Pro 6815

Fit For Hp Officejet Pro 6812

Fit For Hp Officejet Pro 6835

Packing includes:

1 x 934 935 print head

Shipping:

1. Free shipping

2. Parcel will be delivered 3-8 working day

3. Parcel will delivered via Fedex or USPS

Warranty:

Guarantee Period:1 Years

Guaranteed Fitment:Always the correct part means that you can always order with confidence.

Returns & Refunds:Customers can return the goods within 60 days of receipt and process quick refund within one day

Note:

1.In print entered please turn off the power of the printer, or it will cause the mainboard chip burned.

After loading the print head, please don't install ribbon overhead 10 pieces of A4 document,

so that make the new needle have a running-in process, and then put the ribbon. I hope you can be careful operation.

2.If the original print head was broken and especially leaked ink, the mainboard has burned possibly,

so please troubleshoot the problem of the mainboard before replacing the print head. In addition,

the F1,F2 fuze wire of mainboard can only be replaced by the original fuze that has same current value and same model.

If replacing fuze that is biger current value and different model, Both printhead and mainboard are possible to be broken.

3.Print head requires lots of attention, It is easy to cause man-made damage if a non-professionals replace printhead blindly.

There is a regulation that printhead is not warranty, and it is delicate and expensive.

please do not make commissioning on the machine, and please treat it with caution.

4.If you are not familiar with the machine, it is recommended that you had better send the print head to a repair station

or find professionals to replace the nozzle, so as to avoid unnecessary losses and unnecessary trouble.