Product Description

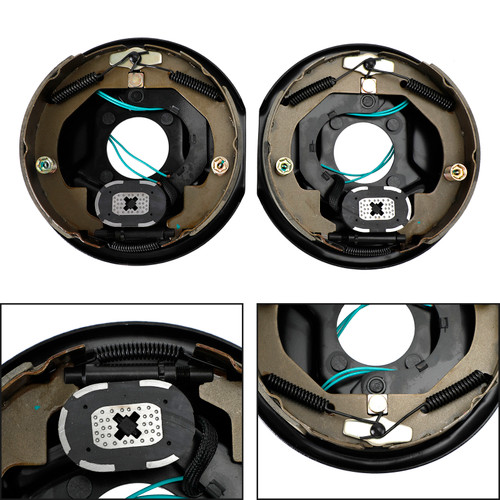

Driver's-side and passenger's-side electric brakes measure 10" x 2-1/4". Brake pads are made of durable friction material for improved braking and longevity. E-coated backing plates resist rust. Fit 14" to 15" wheels.Features:

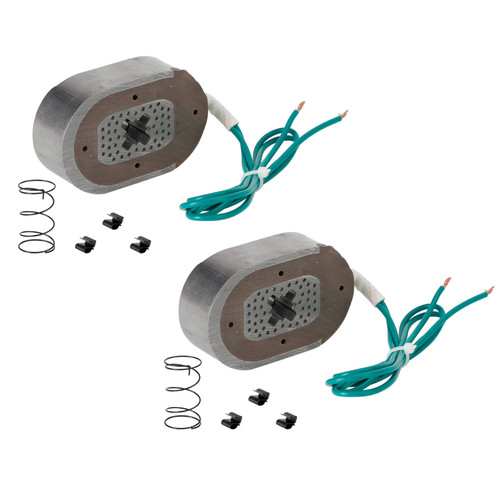

Electric brakes are easier to install and offer more user control than hydraulic brakes

Require only an electric brake controller - no actuator or hydraulic lines necessary

Automotive-grade friction material is molded to brake shoes

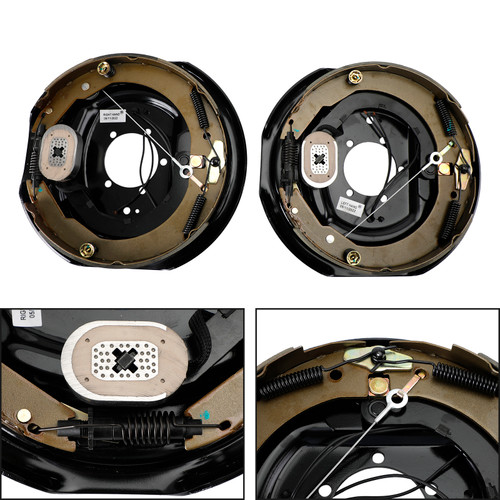

Pads are fully bonded - not riveted - to shoes for long life and more braking torque

Less chance of cracking and crumbling that can lead to mechanical lockup, thanks to tapered edge and circular grinding

Periodic manual adjustment required

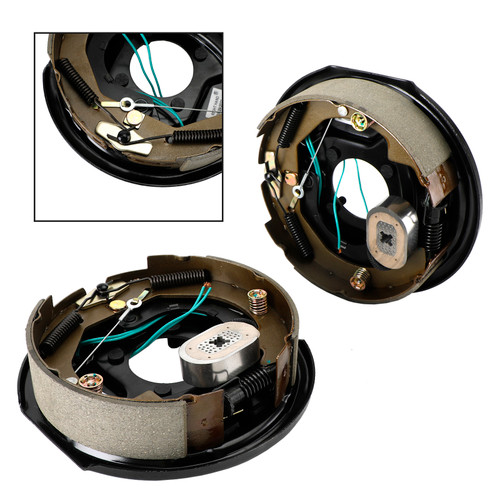

Fine-tooth brake adjustment gears allow for a more precise setting

E-coated backing plates resist wear and corrosion

Adjuster plugs (included) cover access holes to keep dirt and grime out of the assemblies and off of the shoes

Left-hand (driver's-side) brake assembly, right-hand (passenger's-side) brake assembly, and mounting bolts included

QAI and CSA certified

Specs:

Application: most standard hub-and-drum assemblies, including Dexter, Lippert (LCI), and AL-KO

Dimensions: 10" diameter x 2-1/4" wide

Mounting flange bolt pattern: 4 bolt

Wheel size: 14" and 15"

Axle rating: 3,500 lbs

Manual-Adjust Brakes

With repeated use of these brake assemblies, the brake shoes may move out of alignment, causing less efficient braking performance. To keep the brake shoes aligned and the brake assemblies performing correctly, you should perform routine maintenance.

These brake assemblies should be adjusted after installation and then as needed for the life of the brakes. To adjust the brakes, use a brake adjustment screw tool to turn the adjustment gear on the inside of the assemblies. Continue to turn the gear until the drum surrounding the brake catches on the brake pads enough so that the hub can no longer be turned easily by hand. Then reverse the gear by about 10 clicks. A properly adjusted brake should drag slightly on the brake drum.

Thoroughly Tested for Safety

These brake assemblies meet the requirements for certification by the Canadian Standards Association (CSA). The CSA creates standards, which when complied with ensure a safe and quality product. These brake assemblies underwent extensive testing to measure stopping distances when braking. These brakes have also been tested by QAI for braking performance in a complete automotive setup and under real-world conditions to provide the most realistic scenario for the everyday driver.

Automotive-Grade Friction Material

Each shoe on these brake assemblies is lined with automotive-grade friction material for improved stopping performance and longevity. The friction material is fully bonded onto the surface of the brake shoe. This lining is custom-molded for a perfect fit. The edges are tapered to ensure long-lasting performance. This taper, along with the circular grinding that the lining undergoes, helps to prevent cracking and crumbling. This durability helps to prevent mechanical lockup, which can occur when brake shoes are excessively worn or broken.

The friction material is also SAE-N certified, which means that it is an environmentally safe product that complies with California and Washington regulations regarding the composition of brake pads. As a result, this material not only provides high-performance braking that can endure the test of time, but it is also environmentally friendly and safe for use throughout the United States and Canada.